1 INTRODUCTION

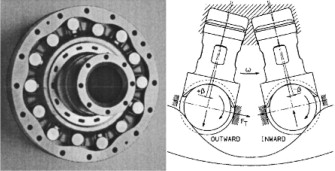

The radial piston hydraulic motor has radial pistons with constant displacement, (see fig. 1), and is used in low speed and high torque applications. It has an even number of pistons that operate in sequences of working pressure and charge pressure in a reciprocating motion. The hydrostatic pressure and oil flow corresponds to actual torque and speed respectively. When torque and rotational speed are produced, as in driving mode, the pistons move outwards under working pressure and inwards under charge pressure. The hydrostatic pressure is constant but differs in magnitude for inward and outward movements. The casing is stationary, which means that the cylinder block and piston assembly rotates. Between the end positions of a stroke, the piston tilts 2ß due to the changed direction of the tangential force and clearance.

This kind of motor can provide very high torque in a relatively compact space. This makes them suitable for heavy-duty applications such as rock crushing, winches, and drilling equipment.

The efficiency of the motor depends on the piston ring-liner oil film since the function of the piston ring is to seal off the high hydrostatic pressure acting on the piston. If the film is too thick then oil flow is increased and hydraulic efficiency is reduced. If the oil film is too thin, then friction is increased, and piston ring failure is possible [1, 2]. A method for the measurement of oil films in-situ would prove useful in the design of piston ring components.

In the past capacitative methods [3] and resistive methods [4] have been used to measure piston ring oil films with some success; however this requires electrical isolation of the sliding components or the use of flush mounted probes. Laser induced fluorescence [5] has been used to measure the oil layer on a cylinder wall as the piston passes. A laser channelled through a fibre optic and a window in the cylinder is used to determine oil fluorescence. Films of the order of 3 to 6 pin were recorded in a fired engine as the rings passed the window location.

In this study an ultrasonic technique is evaluated with the help of a piston-liner bench test apparatus. This approach has the advantage that it does not require the use of windows or surface mounted probes. The reading can be taken non-invasively by passing the sound wave through the cylinder wall.